Transforming the ready-mix industry with cutting edge solutions

SMARThatch Measurement Features

SMARThatch is an advanced measurement system designed to provide actionable data in real time to your entire team. The SMARThatch system replaces the access hatch on any Ready-Mix Truck. Measurement data is displayed in the mixer cab and anywhere your team has cloud access.

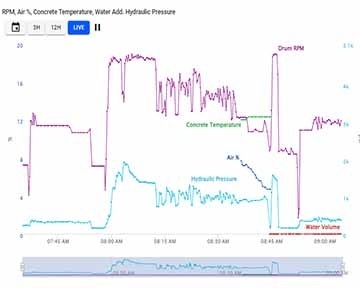

Air Content

Leveraging the proven acoustic measurement system developed by CiDRA for heavy industrial applications, SMARThatch continuously measures Air Content in fresh concrete.

Volume In Drum

Managing returned material is a regular challenge. Stop guessing and know what’s coming back. The SMARThatch system measures yards of concrete from 5 to less than 1.

Temperature

Monitor the temperature of your material, watch for changes and arrive on site with confidence that you are in spec every time.

Drum Counters

SMARThatch continuously measures drum speed in RPM indicating charge direction, revolution counters, and total elapsed time mixing.

Water Meter & Hydraulic Pressure

The two add-on components of the SMARThatch system are an integrated water meter and hydraulic pressure meter. Monitor and record any water added and estimate slump in real time for your entire fleet.

Empower Your Team

A Modern Tool for QC

- Delivers fleet visibility to the team

- Continuous measurement of the entire load

- Reduce manual sampling and testing

Save Time & Money

- Reduce rejected loads

- Manage returned material

- Better yield estimates & control

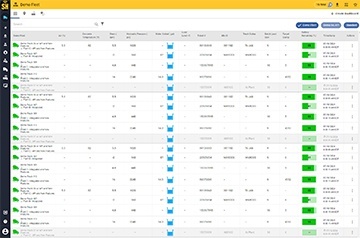

Modern Dashboard Management

The SMARThatch customer portal allows for a real-time measurement and a complete view for any Ready-Mix concrete truck.

The system delivers continuous measurement of Air Content, Temperature, Revolutions, Water Added and Hydraulic Pressure.

Your Data Where You Need It

Data is displayed in the truck cab and in the cloud to any authorized team member with internet access.

With individual permissions and unlimited users, your entire Team can access the data they need anywhere through the SMARThatch Data Portal.

WHAT OUR CUSTOMERS SAY ABOUT US

“We have 8 drivers that are extremely excited as they all love operating trucks with SMARThatches. This is showing me how much our drivers care about what they are doing to deliver high quality concrete in spec every load. Thank you to everyone at CiDRA, Custom-Mix is a huge fan. Thanks again”

JOHN PIPHER,

President – Custom-Mix Concrete

“CiDRA pivots for the company for different needs, requests, and unique asks. We have trust and have seen the data comparison. We had 12 systems and have ramped up to 150. We can adjust at the plant, we can adjust in transit, and we can adjust at the job.”

HEATHER BROWN PHD,

Vice President of QC/QA, IMI – Irving Materials, Inc.

“I strongly believe SMARThatch will soon become an industry standard. The acoustic technology does not depend on middle of the load sampling, complicated and error prone equipment, multi-operator variations, inaccurate computations or calculations. Perhaps the greatest advantage of the SMARThatch is allowing the producer “Total Air Management” in real-time on every load of concrete leaving the plant.”

KEVIN E. MILLER,

Tilcon, Head of Quality Control – Retired

“It allows us to be proactive instead of reactive. It gives me the ability to close the loop on mix design. [We are] saving loads of concrete on a day to day basis… lost loads are trending in the right direction. [With SMARThatch] we have less variation in the batching from batch to batch. [SMARThatch] is making the humans more effective in their process”

BURNCO, NORTH COLORADO READY-MIX

Dana Rotkovich Operations Manager, Burnco Ready Mix, Denver Colorado