Why use the SMARThatch?

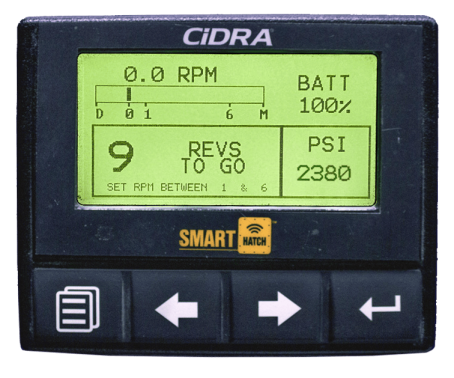

The SMARThatch system is installed on the truck mixing drum providing continuous real-time air, temperature, hydraulic pressure, returning volume, water added, drum rotation, speed and direction measurements from batch plant to job site. The system measures air content in wet concrete as the drum rotates, providing operator and quality control personnel with air information that was never available before. The producer can take action to adjust air content before arriving at the job site and on subsequent batches to ensure the mix will be within specification.

With our patented SMARThatch system, concrete producers can better understand and optimize mix designs, expand their QC coverage, spend less time on job site and catch problems early. All of this translates into increased productivity, reduced waste, lower costs and enhanced competitiveness.

Reduces rejected loads.

Provides the ability to make better quality concrete and control risk.

Reduces time, labor, and the variability related to manual testing.

Provides better yield estimates & control.

Allows for continuous measurement of the entire load vs. traditional pressure pot small fraction sample testing.

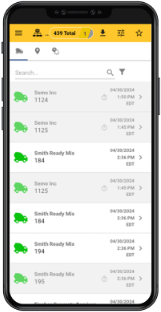

Increases the quality control coverage and accessibility company wide.

Alerts all key personnel to out-of-specification concrete loads allowing for streamlined and efficient mitigation.

Comprehensive training and ongoing support provided by CiDRA Concrete.

Reduces rejected loads.

Provides the ability to make better quality concrete and control risk.

Provides better yield estimates & control.

Reduces time, labor, and the variability related to manual testing.

Allows for continuous measurement of the entire load vs. traditional pressure pot small fraction sample testing.

Increases the quality control coverage and accessibility company wide.

Comprehensive training and ongoing support provided by CiDRA Concrete.

Alerts all key personnel to out-of-specification concrete loads allowing for streamlined and efficient mitigation.

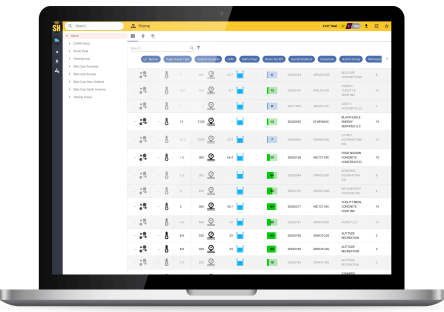

SEAMLESS INTEGRATION INTO YOUR SYSTEMS

We Work with the Same People You do, and Others

Technology, Integration & Data Analysis

At CiDRA Concrete, innovation and technology drive our operations. Our SMARThatch technology provides advanced concrete quality control with real-time monitoring, offering insights into:

• Live Air Percentage

• Live Concrete Temperature

• Live Drum RPMs

• Live Hydraulic Pressure

• Live Water Added Tracking

• Load Level

• Live Ignition Status

Our extensive partner network ensures seamless integration with systems like ERPs, batch systems, and dispatch systems, removing technical barriers. Job information such as custom names, job numbers, ticket numbers, batch load sizes, mix IDs, mix descriptions, job locations, target slump, target air percentage, ordered quantity, and delivered quantity is accessible through our portal.

At CiDRA Concrete, our commitment to innovation and technology sets us apart in the concrete industry. Our state-of-the-art SMARThatch technology is at the forefront of concrete quality control, providing unparalleled real-time monitoring and data insights to ensure optimal performance and consistency.

Seamless System Integration

Our extensive partner network ensures that SMARThatch integrates seamlessly with existing systems such as ERPs, batch systems, and dispatch systems. This integration removes technical barriers and enhances operational efficiency. Key job information accessible through our portal includes:

• Custom names

• Job numbers

• Ticket numbers

• Batch load sizes

• Mix IDs

• Mix descriptions

• Job locations

• Target slump

• Target air percentage

• Ordered quantity

• Delivered quantity

Key Benefits of SMARThatch Technology

• Enhanced Quality Control: Real-time data allows for immediate adjustments, ensuring high-quality concrete with every load.

• Operational Efficiency: Integration with existing systems streamlines processes, reducing downtime and errors.

• Safety and Compliance: Continuous monitoring helps maintain safety standards and regulatory compliance.

• Data-Driven Insights: Access to detailed data enables better decision-making and process optimization.

Application

Replacing the existing Ready-Mix hatch allows for a Plug and Play installation. The only solution in the industry that measures real-time air content.

Streamlines operations and responsibilities for:

• Plant Managers

• Drivers

• Sales Representatives

• Quality Control Technicians

• Owners

• And More.

WHAT OUR CUSTOMERS SAY ABOUT US

“CiDRA pivots for the company for different needs, requests, and unique asks. We have trust and have seen the data comparison. We had 12 systems and have ramped up to 150. We can adjust at the plant, we can adjust in transit, and we can adjust at the job.”

HEATHER BROWN PHD,

Vice President of QC/QA, IMI – Irving Materials, Inc.

“I strongly believe SMARThatch will soon become an industry standard. The acoustic technology does not depend on middle of the load sampling, complicated and error prone equipment, multi-operator variations, inaccurate computations or calculations. Perhaps the greatest advantage of the SMARThatch is allowing the producer “Total Air Management” in real-time on every load of concrete leaving the plant.”

KEVIN E. MILLER,

Tilcon, Head of Quality Control – Retired

“It allows us to be proactive instead of reactive. It gives me the ability to close the loop on mix design. [We are] saving loads of concrete on a day to day basis… lost loads are trending in the right direction. [With SMARThatch] we have less variation in the batching from batch to batch. [SMARThatch] is making the humans more effective in their process”

BURNCO, NORTH COLORADO READY-MIX

Dana Rotkovich Operations Manager, Burnco Ready Mix, Denver Colorado